News

Home News Technical articles Microporous membrane pleated filter element in red wine filtration industry

Home News Technical articles Microporous membrane pleated filter element in red wine filtration industry

Microporous membrane pleated filter element in red wine filtration industry

2024-03-24 Eternalwater Wine is an important drink in our daily lives. As people's drinking habits gradually develop toward nutrition, enjoyment, and health care, the demand for high-end, high-quality whole juice wine is constantly increasing. Briefly understand the microporous membrane filter element Filtration related applications in the red wine industry.Red wine making process

Wine is an alcoholic beverage made from fermented fresh grapes or grape juice, usually divided into red wine and white wine . It is made by macerating and fermenting the skins of red grapes; the latter is made by fermenting the grape juice. The winemaking process can be divided into two parts: the first part is fermentation , that is, the process in which grape juice turns into wine; the second part is aging into wine , that is, the process in which newly fermented wine changes from immature to mature and refined. Taking red wine as an example, it is slightly different from home-made red wine. The specific steps of making red wine in a winery (factory) include: grape picking - skin breaking and stem removal - skin soaking and fermentation - juice pressing and post-fermentation - oak barrels Culture-clarification, bottling and other steps, see the flow chart for details.

The fermentation principle of wine:

Yeast type: wild yeast

Fermentation principle: When there is a lack of oxygen, fermenting yeast will perform anoxic respiration, in which glucose is converted into pyruvate through glycolysis, and then pyruvate removes carbon atoms through decarbization to form acetaldehyde and ethanol. , releasing CO2 at the same time.

Why wine needs to be filtered

On the one hand, the brewing process of red wine is relatively complicated. After the alcoholic fermentation is completed, the skin residue in the wine has no use for the wine. If it is not filtered out, it will increase the sediment in the wine and affect the taste. In addition, the skin residue may contain other microorganisms, and long-term soaking may also affect the stability of the wine, which is not conducive to long-term storage.

Therefore, filtration and clarification are an important process in wine production. By controlling the precision of filtration, not only can good sensory quality be obtained, but also microorganisms in the wine can be effectively removed to achieve aseptic filling.

Clarification: After the fermentation of the wine is completed, some pomace and yeast may remain in the wine, making the wine look less clear, and there is a potential risk of spoilage. Therefore, these substances are removed from most wines before bottling to purify the wine and improve stability. This process is called fining.

Filtration: Use physical methods to quickly remove suspended solids from wine through the use of filters. This method can be divided into depth filtration and surface filtration. Among them, depth filtration filters usually have thicker membranes and can remove coarse particles and are suitable for turbid wines; surface filtration filters have thinner membranes. The flow rate is faster and easier to clean, removing yeast and bacteria from the wine.

How to filter wine

Filtration removes solid particles from wine through a water-permeable material. It can process relatively turbid wines and remove more precipitated residues in the wine. Common materials include diatomaceous earth, whose surface is a layer of fiber. After this part of filtration, subsequent procedures such as fine filtration and sterilization filtration are still required to complete the process. of wine. Among them, membrane filtration is widely used in the wine production industry and is an essential operating unit. The core component of membrane filtration is the membrane filter element , whose main features are: high filtration precision and high efficiency. In the wine filtration process, the filter element is generally used with a precision of 0.2-0.45μm, which can filter out yeast and bacteria in the wine and prevent re-fermentation during storage. Here is an introduction to the conventional wine filtration process.

Among them, the membrane filter element has the following functions at the main filtration points of wine:

1. Clarification and filtration: remove particulate impurities shed from the water and upstream2. Pre-filtration: remove impurities such as large particles and protect the life of downstream sterilization filtration

3. Sterilization filtration: remove yeast, spores, particles and microorganisms, etc.

4. Gas sterilization filtration (air, CO2, N2, respirator): Compressed air, N2 and CO2 remove moisture and particles in the gas to achieve sterilization level; the respirator balances the pressure inside and outside the tank and protects the tank and the tank. reclaimed water

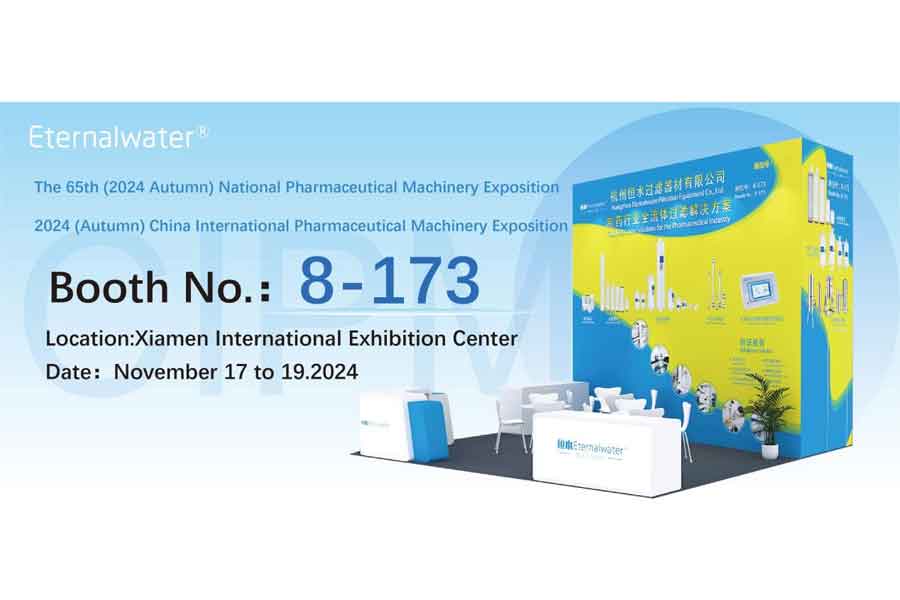

pleated filter cartridge factory

Latest News

Read more

- Industry Application

- Life Sciences

- water treatment

- Industrial Filtration

- Food & Beverage

- Microelectronics

- Laboratory

- New energy battery

- Contact Us

- [email protected]

- +86-571-87022016

- +86-571-87293027

- +8613675899519

- Subscribe for Join Us!

- Join us and get detail information,technical parameter and new products etc.

CopyRight © Hangzhou Eternalwater Filtration Equipment Co., Ltd. 2002-2025

- [email protected]

- Jenny wu

- +8613675899519

- +86(571) 87022016

EN

EN  ES

ES AR

AR JP

JP CN

CN