EW-F48 Series Automated Filter Integrity Tester

- Product features

- 1.High-performance CPU, touch screen design, simple,fast and reliable operation.

2.Powerful storage function, data can be queried at fixed points or under specific conditions, and the built-in printer can quickly print test results, historical data, and real-time data curves.

3.The test speed is fast.

4.Small size, light weight, low energy consumption and easy to carry.

5.Splash-proof technology IP54 specially designed for production environments.

- Industry Application

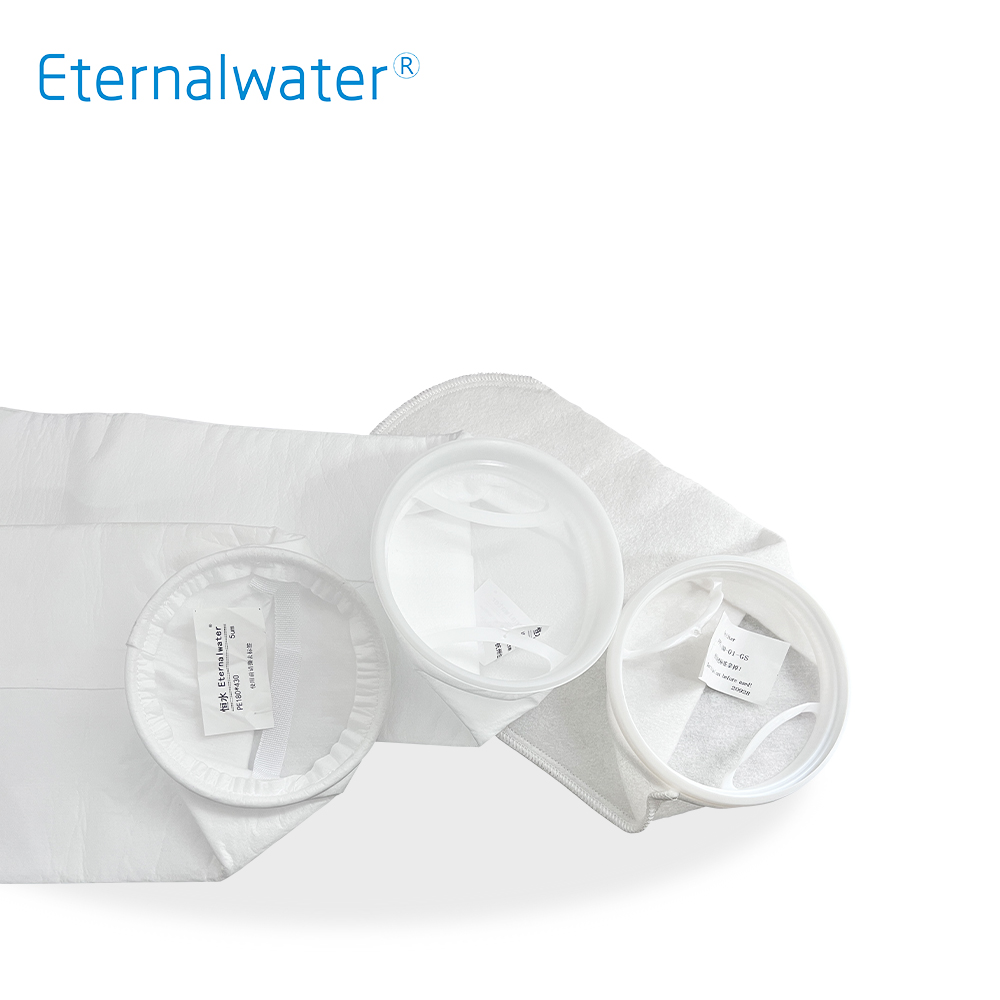

- 1.Pharmaceutical industry: Integrity test of various hydrophilic and hydrophobic filters, including pleated filter cartridges, capsule filters, flat filter membranes, and membrane bags.

2.Food industry: filters for alcohol, mineral water and drinking water.

- DOWNLOAD

- INQUIRY NOW

- Input Voltage:

- (100-240)V AC

- Input Frequency:

- 50/60Hz

- Input Power:

- 160W

- Sensitivity (Forward Flow) :

- 0.01mL/min:0.01mL/min

- Sensitivity (Water Intrusion):

- 0.01mL/min:0.01mL/min

- Sensitivity (Bubble Point):

- 1mbar

- Repeatability:

- ≤3%

- Test Accuracy ( Forward Flow) :

- ±4% or 0.1mL/min,take the larger value

- Test Accuracy ( Water Intrusion):

- ±4% or 0.02mL/min,take the larger value

- Test Accuracy (Bubble Point):

- ±50mbar

- Test Range ( Forward Flow):

- (0.1-600)mL/min

- Test Range (Water Intrusion):

- (0.01-100)mL/min

- Test Range ( Bubble Point):

- (100-8000)mbar

- Test Range ( Pressure Maintenance ):

- (100-8000)mbar

External Features

Waterproof and Dustproof Design

The protection level of IP54 prevents the short circuit of the instrument caused by sudden splashing of water during the test.

Anti-Backflow Design of Pipelines

It can be quickly cleaned to prevent liquid backflow and prevent microbial pollution to the upstream of the filter.

Full Touch Screen Operation10

10-inch large screen, high resolution, easy to click.

Dust-Free Hi-Fi Printing Technology

Data results can be generated efficiently and quickly and stored for a long time, with a storage period of more than 10 years.

Offline Test

Can be connected to wireless networks, local area networks, and support remote data management and synchronization.

Fully comply with data integrity requirements

Fully comply with GMP and 21 CFR Part 11 requirements for electronic data integrity, 4 levels of password permissions, audit trail function, multiple forms of backup.

Gas Circuit Connection Diagram of Integrity Tester

Integrity Tester Precautions

1.The gas tightness of the instrument and system.

2.The sealing of the filter cartridge end cap and filter socket.

3.For bubble point and forward flow, please pay attention to whether the filter cartridge is completely wetted, and water intrusion requires that the filter cartridge is strongly hydrophobic and dry.

4.Determine the type of filter cartridge. Only absolute membrane filter cartridges can be tested for integrity, such as PES, PTFE, PVDF, NY66, etc.

5.The gas pressure needs to be at least 1000mbar higher than the test bubble point.

- Industry Application

- Life Sciences

- water treatment

- Industrial Filtration

- Food & Beverage

- Microelectronics

- Laboratory

- New energy battery

- Contact Us

- [email protected]

- +86-571-87022016

- +86-571-87293027

- +8613675899519

- Subscribe for Join Us!

- Join us and get detail information,technical parameter and new products etc.

- [email protected]

- Jenny wu

- +8613675899519

- +86(571) 87022016

EN

EN  ES

ES AR

AR JP

JP CN

CN